Kate Walker here, keeping the light on Robbins Reef.

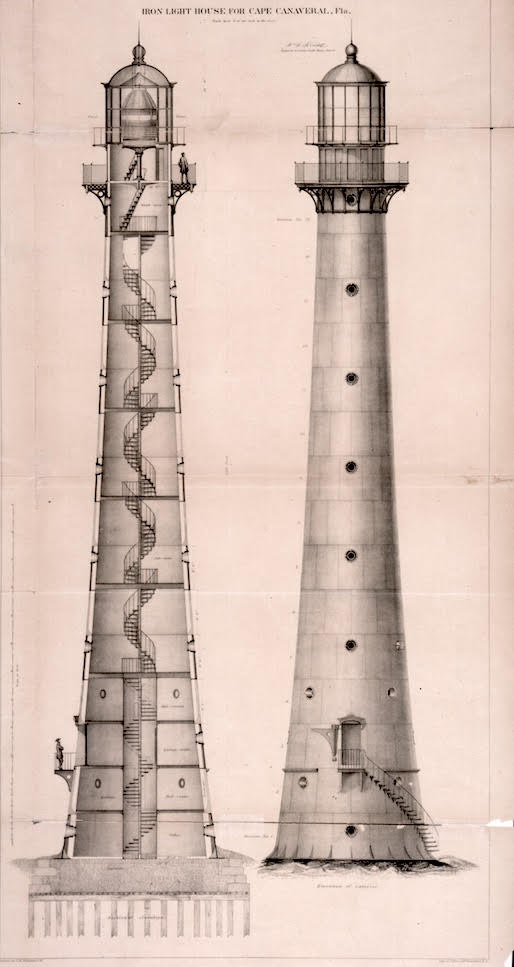

The earlier lighthouse on Robbins Reef was built of stone, but my tower was built of cast-iron plate. Cast iron became a very useful material in the second half of the 19th century because it was lightweight and watertight. A cast-iron tower could be made in sections, easily transported, and assembled at the site. It could also be taken down, moved, and reassembled. When lighthouses constructed of masonry sank or blew over, having no solid footing, they were often replaced with much lighter cast-iron structures.

During the Civil War the Confederates took down the cast-iron tower at Bolivar Point in Texas plate by plate. When the war ended, the sections of the tower’s one-inch-thick cast-iron skin were never found, probably having been used to make armaments.

The Boca Grande Rear Range Lighthouse in Florida served as the Delaware Breakwater Rear Range until 1918. When the tower was offered to the various lighthouse districts, the 7th district superintendent claimed it and erected it on Gasparilla Island.

I wondered how they put the huge 1st-order Fresnel lens into such a tall tower. On June 17, 1895, the lens, which had been sent to Baltimore from the general depot on Staten Island, New York, was taken to the station by the tender Jessamine. A hoisting engine was set up, a mast erected on the watch room gallery, with the necessary pulleys and rigging, and the parts of the lens apparatus were hoisted outside the tower into the lantern, where they were properly arranged and bolted together by lampists—men specially trained to assemble and maintain lamps and lenses.

Information from Clifford, Nineteenth-Century Lights, pp. 23, 195; 1895 Annual Report of the U.S. Light-House Board; David Cipra, Lighthouses, Lightships, and the Gulf of Mexico; National Archives Record Group 287, Box T683

Information from Clifford, Nineteenth-Century Lights, pp. 23, 195; 1895 Annual Report of the U.S. Light-House Board; David Cipra, Lighthouses, Lightships, and the Gulf of Mexico; National Archives Record Group 287, Box T683

Submitted September 28, 2017

* * * * *

U.S. Lighthouse Society News is produced by the U.S. Lighthouse Society to support lighthouse preservation, history, education and research. Please join the U.S. Lighthouse Society if you are not already a member. If you have items of interest to the lighthouse community and its supporters, please email them to candace@uslhs.org.

Kate, Thanks for all the good work and the great information. We appreciate it. If you think about it, Cape Charles is also the second tallest tower in the USA. John Mann Lead Docent Ponce Inlet Lighthouse